What are management systems?

Management systems are among the most effective methods for improving the quality of products and the satisfaction of employees and customers. It is a construct of processes and procedures that serve to optimize company processes, save resources, operate sustainably and continuously develop the organization. This continuous improvement process (CIP) is achieved with the PDCA cycle (plan-do-check-act), i.e. new targets are set after each purchase and reviewed again at the end and/or measures are adjusted accordingly.

1. plan: planning of relevant activities and definition of objectives

2. do: implementation of measures

3. check: monitor and check whether planned objectives have been achieved

4. act: take action, i.e. make adjustments and optimizations if goals have not been achieved

The constant repetition of the PDCA cycle leads to the continuous improvement of the performance of the management systems, i.e. all management systems follow the same logic – only with consideration of different topics.

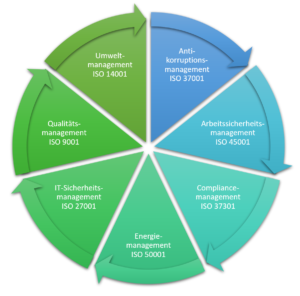

In order to better implement and compare the respective requirements of the different areas, a large number of standards have been developed. The best-known standards for management systems include ISO 9001 (quality management), ISO 50001 (energy management), ISO 14001 (environmental management) and ISO 45001 (occupational health and safety).

Why management systems make sense

The introduction of management systems offers many advantages even for small and medium-sized companies:

- Effective & efficient value creation

- Improve economic performance

- Reduce costs & increase profitability

- Recognize opportunities & strengthen market position

- Minimize errors & risks

- Meet customer requirements & increase customer satisfaction

- Continuous improvement & measurable process optimization

- Improve legal certainty (compliance management)

- Avoid organizational deficiencies & raise quality levels

- Positive image & competitive advantages

- Promote employee motivation

- Documentation & maintenance of relevant processes

- Systematic prevention and improved coordination

Unser Service für Sie

Beratung und Unterstützung bei der Einführung und Aufrechterhaltung Ihres Managementsystems:

- Qualitätsmanagement DIN EN ISO 9001

- Medizinprodukte – Qualitätsmanagementsystem DIN EN ISO 13485

- Umweltmanagementsystems DIN EN ISO 14001

- Treibhausgase DIN EN ISO 14064

- Lebensmittelsicherheit DIN EN ISO 22000

- Anti-Korruptionsmanagement DIN EN ISO 37001

- Compliance-Managementsystem DIN EN ISO 37301

- Sicherheit und Schutz des Gemeinwesens DIN EN ISO 22301

- IT-Sicherheitsmanagementsystems DIN EN ISO 27001

- Sicherheitsmanagementsysteme für die Lieferkette ISO 28001

- Energiemanagementsystems DIN EN ISO 50001

- Social Management SA 8000

- Ecovadis

Downloads

Further services

Contact

Frequently asked questions

What are management systems?

Management systems are effective methods for improving the quality of products and the satisfaction of employees and customers. They consist of processes and procedures that aim to optimize company processes, save resources, operate sustainably and continuously develop the organization.

What is the significance of the PDCA cycle in the context of management systems?

The PDCA cycle (plan-do-check-act) is a continuous improvement process that is used in management systems. It consists of the steps of planning, implementation, monitoring and adjustment of measures in order to achieve and improve the objectives of the system.

What known standards are there for management systems?

The best-known standards for management systems include ISO 9001 (quality management), ISO 50001 (energy management), ISO 14001 (environmental management) and ISO 45001 (occupational health and safety).

Why are management systems useful?

The introduction of management systems offers companies various advantages:

- Effective and efficient value creation

- Improvement of economic performance

- Reducing costs and increasing profitability

- Recognition of opportunities and strengthening of the market position

- Minimization of errors and risks

- Fulfilling customer requirements and increasing customer satisfaction

- Continuous improvement and measurable process optimization

- Improving legal certainty (compliance management)

- Avoiding organizational deficiencies and increasing the level of quality

- Positive image and competitive advantages

- Promotion of employee motivation

- Documentation and maintenance of relevant processes

- Systematic prevention and improved coordination

What services do you offer in the area of management systems?

We offer advice and support for the introduction and maintenance of various management systems, including quality management, medical device quality management system, environmental management system, energy management system, IT security management system and others.