Research

Search

Use the search to find a published research article.

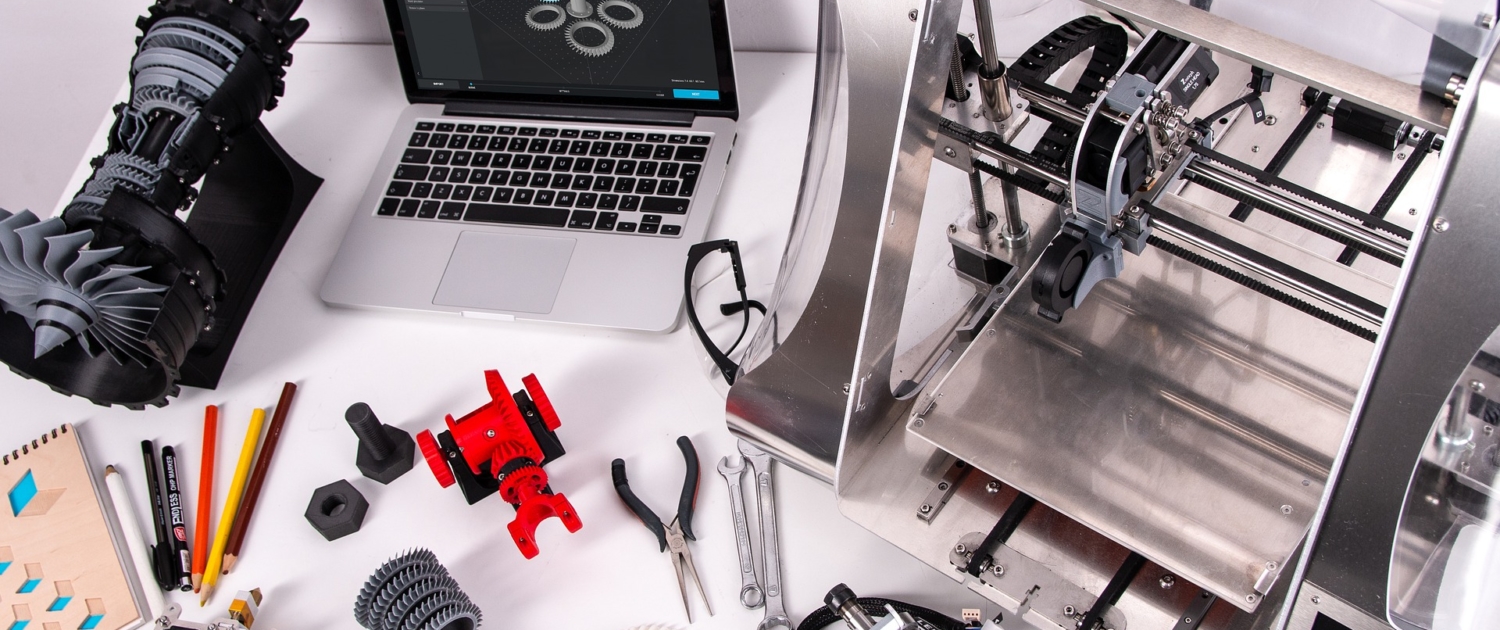

We are not only a company that specializes in certain products or services, but we are also actively involved in research and development. On this page, we would like to give you an insight into two of our ongoing research projects: SmartShip and 3D printing optimization.

These projects represent our efforts to drive innovative solutions in the fields of shipping and 3D printing technology. Find out more about our research activities and the exciting developments we are driving forward in these areas.